Hi Bobbin,

I noticed from the archives that you are very experienced in slipcovers, so here goes: How would you approach this?

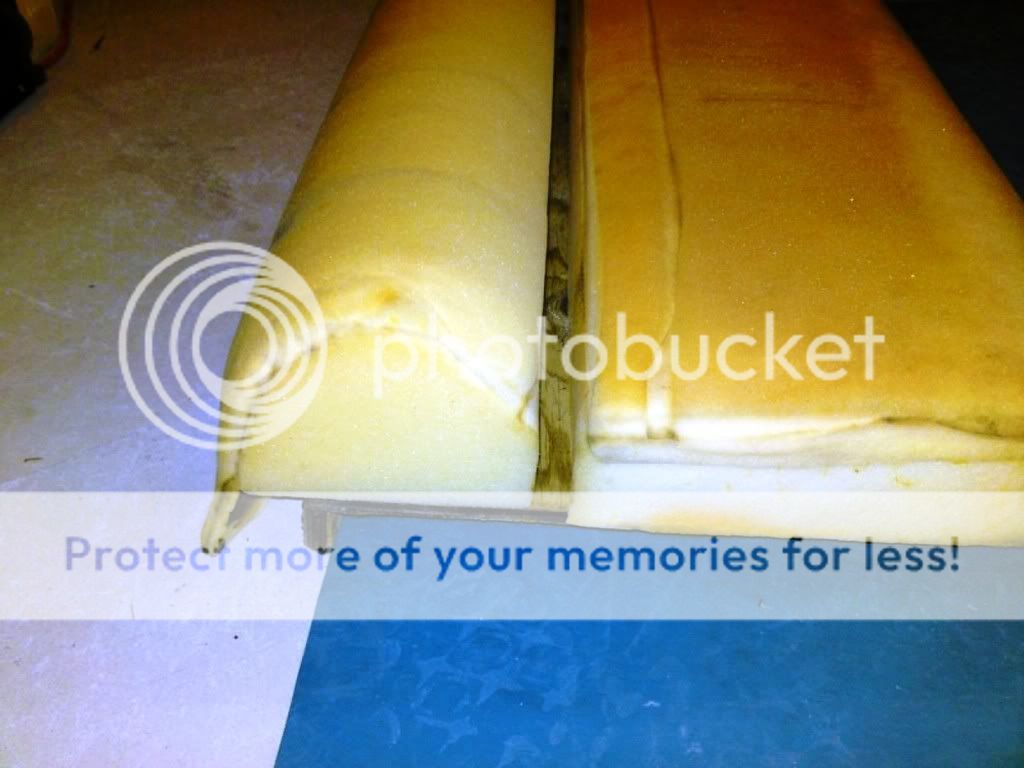

Would you put a boxing strip on the top? Or just a piece for the outside back sewn to the piece for the inside back?

The customer wants it as fitted as possible, with one piece on the inside back. The back cushions are attached, and when I place the fabric over the inside back, all the lines telegraph through the fabric.

I've done 4 slipcovers before, but those sofas were more straightforward than this.

???

I noticed from the archives that you are very experienced in slipcovers, so here goes: How would you approach this?

Would you put a boxing strip on the top? Or just a piece for the outside back sewn to the piece for the inside back?

The customer wants it as fitted as possible, with one piece on the inside back. The back cushions are attached, and when I place the fabric over the inside back, all the lines telegraph through the fabric.

I've done 4 slipcovers before, but those sofas were more straightforward than this.

???