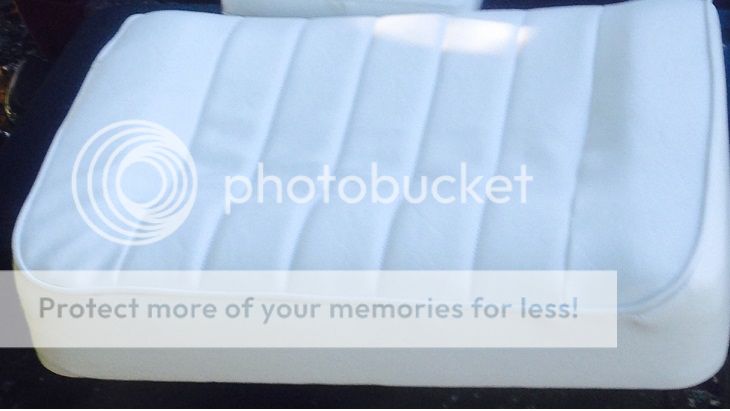

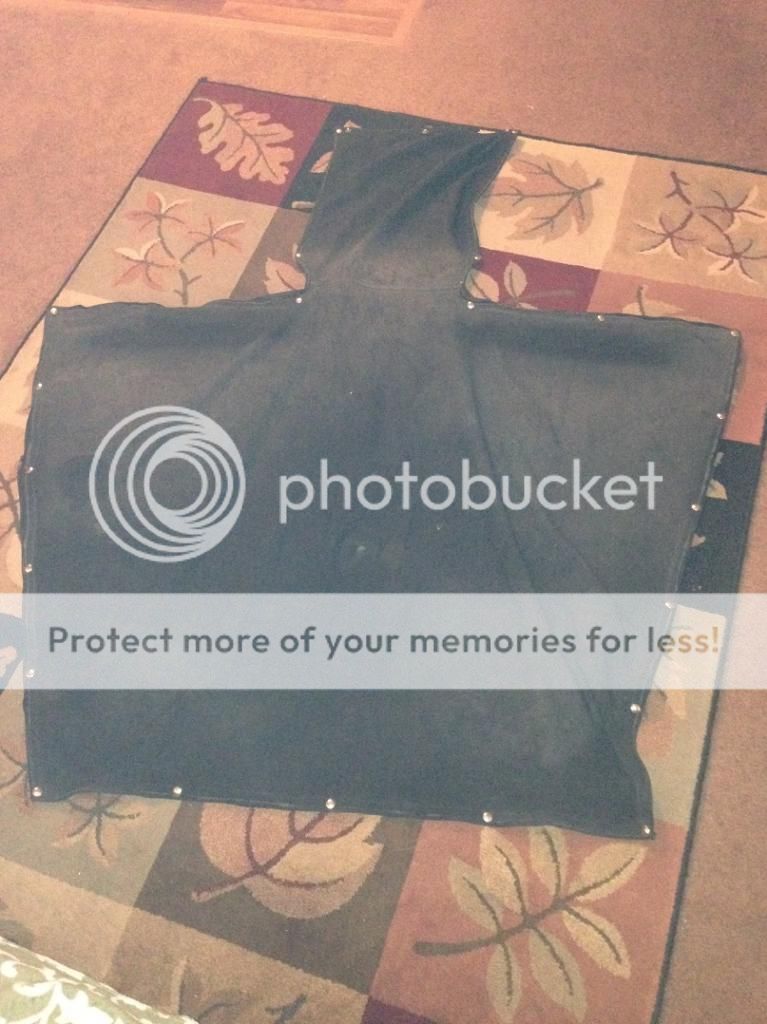

Just wondering what the average cost/pricing would be for a Lazy Boy Recliner Re-Upholstering job. I've has several requests but when I calculate the time + materials costs to do the job, I'm thinking it's not worth my time or the customers money to do the job.

What are you guys charging?

My calculations are $200 for material and $400 labor. Am I way off???

What are you guys charging?

My calculations are $200 for material and $400 labor. Am I way off???