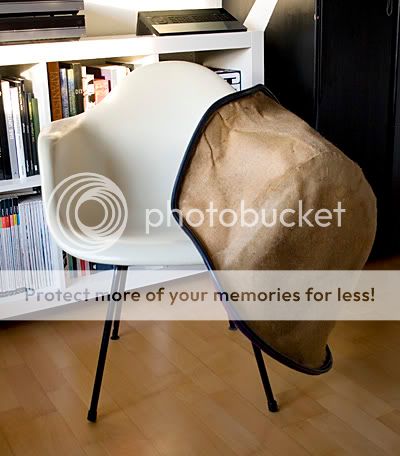

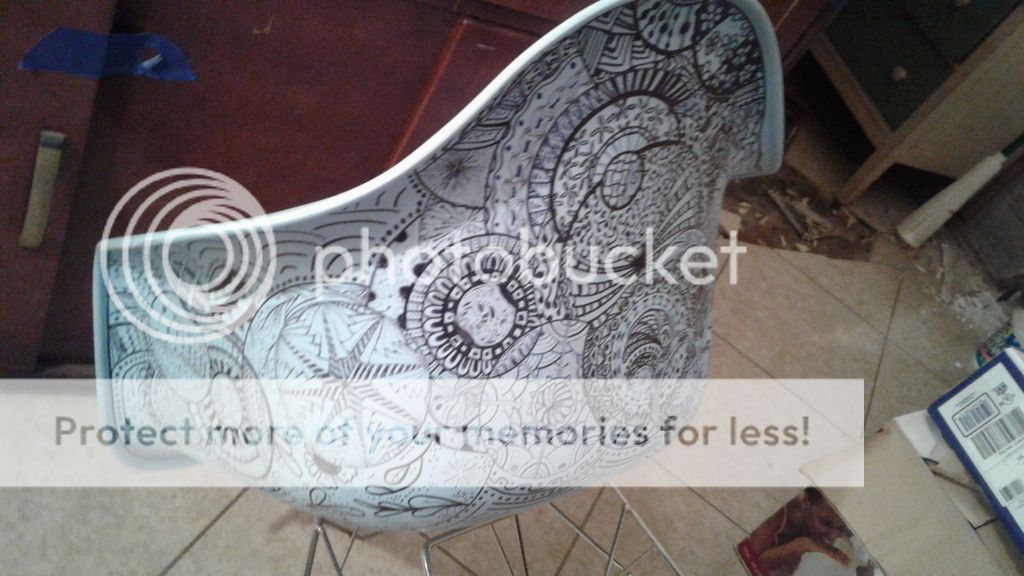

Thanks, that helps a lot. I am going to go with contact cement. This is the chair and the last pic is the fabric I am using. I made the rosewood rocket glides and did the artwork on the back. It is for a show in August and go woth a desk I am building in blackened steel and acacia. Always a bit nervracking trying something new on something you already have a lot of work in. I am thinking coat the fabric but just do a few inched at a time on the foam so I dont risk sticking something where it doesnt belong. Does that sound like a good plan of attack?